At SPS Connect, Bosch Connected Industry will demonstrate that not only consumer products, but also machines can be designed and operated intuitively and cost-efficiently. The new versions of the Nexeed Automation software system “Control plus” as well as the “Virtual Assist” assistance system make the implementation and handling of automation projects very easy, even in special-purpose machine building.

During the development process, the user was at the center of attention: “We involve users in the development process at a very early stage and draw on Bosch’s experience as a leading user and leading provider of Industry 4.0 technologies,” explains Marc Bindel, head of the product area Automation and User Experience at Bosch Connected Industry. The result is a solution that offers greater flexibility to machine builders, as well as machine operators and users.

Control plus V2: cost-effective engineering for machine builders For many years, the automation platform Nexeed Automation is synonymous with efficient and cost-effective modular engineering in special-purpose machine building. Thanks to the Control plus software system based on the IEC 61131 PLC standard and its extensive object library, software projects can be quickly generated and supplemented with process-specific sequences and functions. The user tests for the new version of Control plus focused on optimal system operation and the seamless integration of the assistance systems into the user interface.

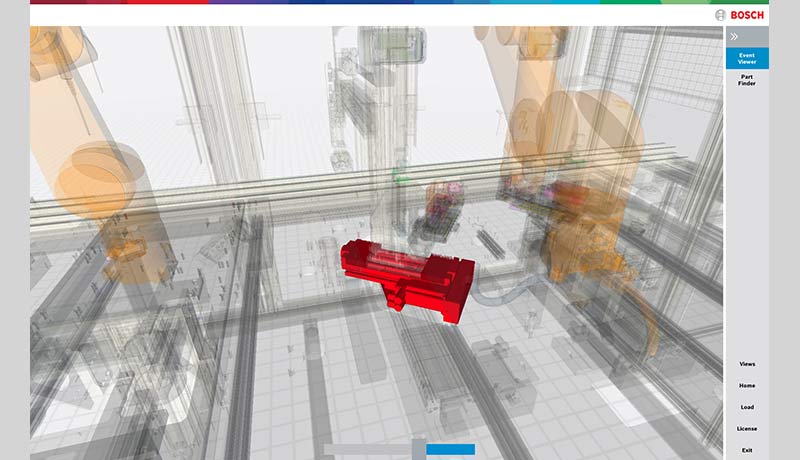

One example is the 3D machine visualization: in contrast to conventional, textbased alarm systems, the Control plus HMI with Virtual Assist directly displays the source of the error. Thanks to color coding, machine operators can see at a glance where an error occurred in the machine. In addition, the assistance system offers the option of recording action lists in a knowledge database, so that errors can be quickly rectified and new or unfamiliar employees can immediately familiarize themselves with the situation. The Virtual Assist assistance system is not limited to Control plus. It can also be used via standard interfaces with control systems from other manufacturers.

“The 3D visualization is unique in its form for special-purpose machine building,” explains Bindel. “So far, it could only be implemented for large series production machines with a great deal of time and, above all, financial effort. Thanks to the new version of Control plus and the Virtual Assist assistance system, this is now possible up to batch size one.” Those who integrate Control plus and the Virtual Assist assistance system into their machines benefit twofold: “We offer initial automation software that is extremely efficient, easy to configure and integrate. This benefits the machine builder, followed by the machine builder’s customers and their machine operators,” says Bindel. Nexeed Automation not only reduces considerable effort in the engineering phase. It also ensures that new systems can be handled quickly.