HP made a set of announcements demonstrating its continued 3D printing and digital manufacturing momentum. Helping expand the overall market and unlock new applications for customers, HP is delivering a first of its kind Polypropylene (PP) material for additive manufacturing. The new HP 3D High Reusability PP, enabled by BASF, is a versatile, durable, and chemically resistant material that has been qualified for HP’s production-grade 3D printing systems, and is ideal for customers in the automotive, consumer, industrial, and medical sectors seeking an optimal balance between performance and cost. HP also unveiled a new partnership with Oechsler, the global design and manufacturing player, to develop applications for both the new PP and HP’s broader materials portfolio, as well as new customer Cobra Golf for its Metal Jet 3D printing technology.

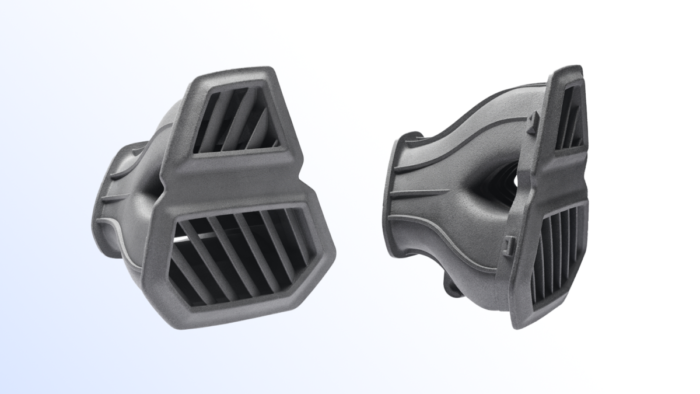

Polypropylene is a versatile material ideal for a wide range of automotive, consumer, industrial, and medical applications. The new HP 3D High Reusability PP enabled by BASF provides customers with a genuine new additive manufacturing material offering the same properties as commonly used PPs in injection molding, which has proven to have nearly unlimited use. With its excellent chemical resistance, low moisture absorption, and long-term durability, PP is ideal for piping, fluid systems, and containers. For example, automakers will be able to use the same PP for prototyping and production of final parts found in vehicles’ interior, exterior, and under-the-hood.

Developed in partnership with BASF for HP’s Jet Fusion 5200 3D Series, the new PP delivers high productivity and minimizes waste for industrial-level manufacturing. In addition to breakthrough economics and performance, the new PP helps reduce waste[i] by enabling up to 100% reusability of surplus powder.

HP is jointly developing entirely new PP applications with partners, parts providers, and customers including Extol, specializing in plastics engineering and innovation with plastic assembly technology, custom automation, and engineering services; GKN Powder Metallurgy /Forecast 3D, a provider of advanced industrial 3D printing, short-run manufacturing, and high-volume production; Henkel, a provider of high-impact adhesives and engineering solutions; Oechsler, an additive manufacturing parts provider; and Prototal, one of Europe’s most experienced parts manufacturers.

To help customers accelerate their journey to digital manufacturing, HP announced new and expanded 3D Professional Services offerings and industrial alliances, including:

Cobra Golf, a provider in golf club manufacturing, innovation and design, has selected HP Metal Jet for its entry into 3D printing for product innovation and parts production.

A foremost innovator in the golf world, Cobra is committed to revolutionary advancements in technology, engineering first-of-its-kind clubs and equipment designed to elevate the game. Cobra, HP, and Parmatech are working together on a strategic multi-year product roadmap, that leverages the design and manufacturing benefits of HP’s additive technologies to deliver golf equipment that raises performance and golfer satisfaction to new levels.