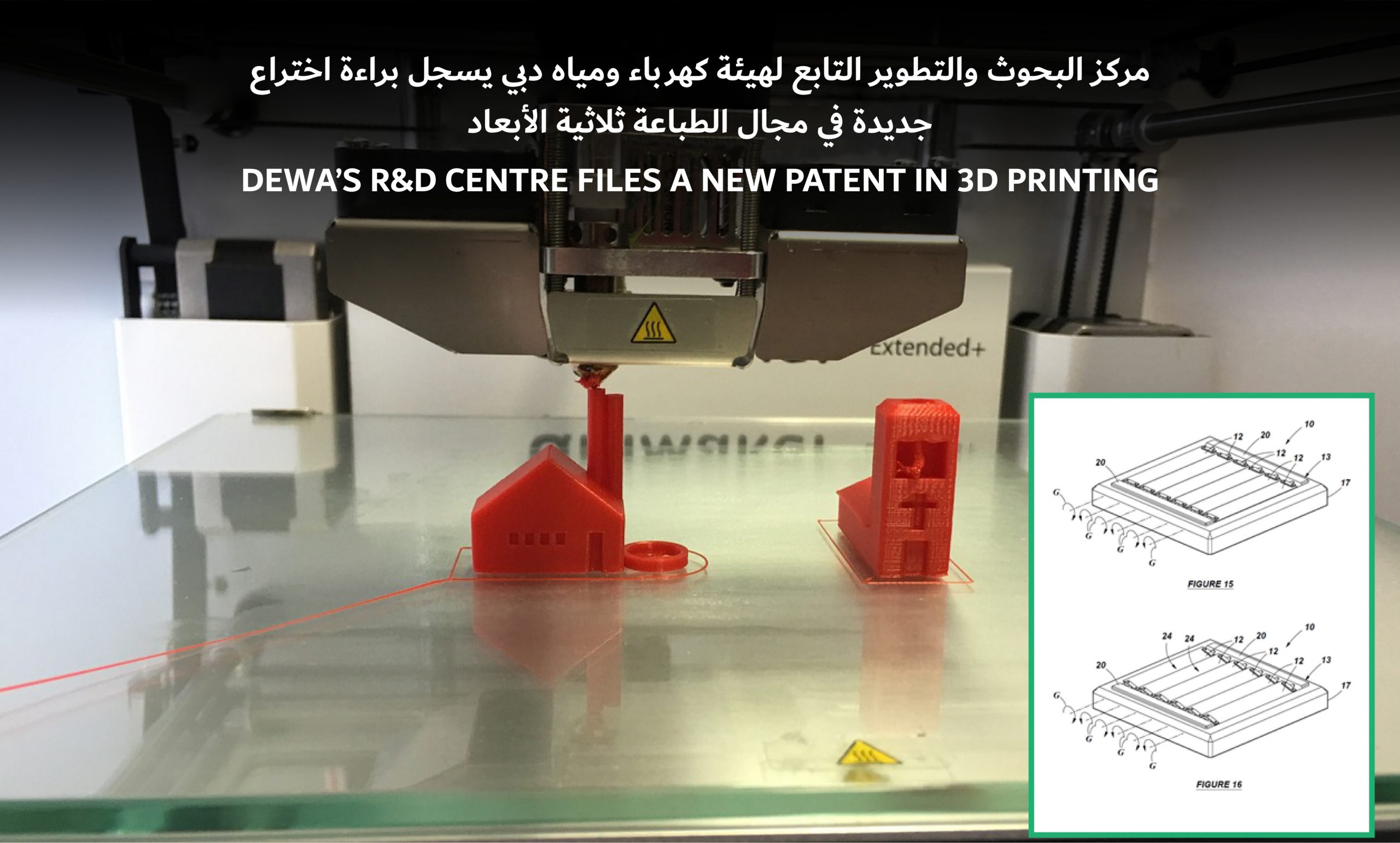

DEWA’s Research and Development Centre (R&D) based in Dubai has recently submitted a novel patent application centered around an inventive build plate and an automated method for detaching 3D printed objects. This development is poised to optimize the efficiency of 3D printers by facilitating the seamless removal of printed objects during the printing process. Consequently, this advancement enables uninterrupted 3D printing operations.

This breakthrough aligns with DEWA’s dedicated pursuit of cutting-edge infrastructure and specialized software for 3D printing and additive manufacturing. These efforts are aimed at surmounting challenges in the energy sector. DEWA effectively employs 3D printers to manufacture prototypes and spare parts for its generation, transmission, and distribution divisions. Furthermore, these printers play a pivotal role in the digital transformation of the organization’s inventory management.

Saeed Mohammed Al Tayer, the MD and CEO of DEWA, emphasized the organization’s commitment to Dubai’s vision of becoming a global focal point for 3D printing. By devising innovative solutions and technologies, DEWA strives to modernize spare parts production, enhance sustainability, and stimulate innovation in manufacturing and operations. This strategy not only results in time and cost savings but also amplifies overall productivity and efficiency.

Within our internal operations, we embrace 3D printing as a groundbreaking solution for crafting spare parts for equipment, thereby extending their operational lifespan. DEWA holds the distinction of being the inaugural entity in the GCC to harness metal 3D printing technology using threads and wires. The organization earned a Guinness World Records accolade for pioneering the world’s first 3D printed laboratory, housing the Robotics and Drone lab, located within the R&D Centre. The Centre further bolsters its reputation through its patent portfolio and advanced research papers, garnering widespread recognition from utility companies worldwide for its 3D printing endeavors.

Waleed bin Salman, the Executive Vice President of Business Development and Excellence at DEWA, underscored the R&D Centre’s transformation into a global hub for innovative solutions and technologies geared towards elevating utility sector operations and services.

A notable accomplishment of the Centre lies in its patent for an adhesive device designed for 3D printers. This device autonomously dispenses adhesive material onto the 3D printing plate, guaranteeing optimal adhesion between the printed material and the build plate.