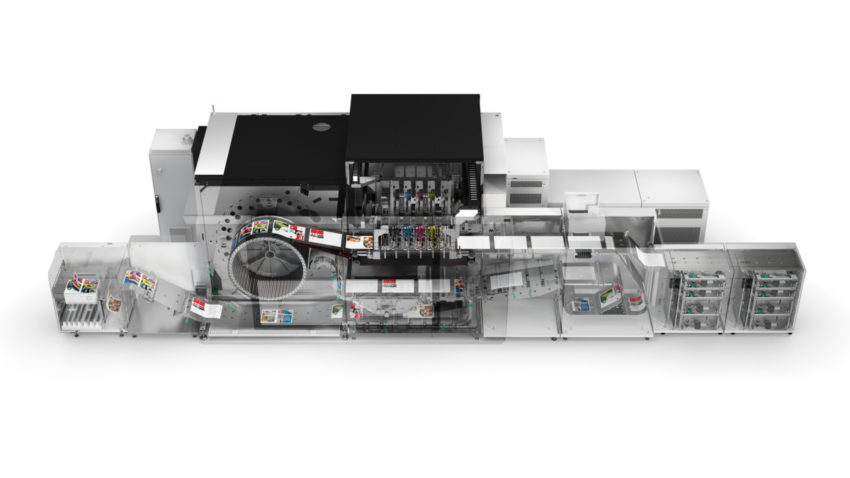

Canon Middle East is announcing the varioPRINT iX-series, an advanced sheetfed inkjet press from Canon featuring iQuariusiX technology. For customers with production volumes of 1 to 10 million A4 images per month, the new press combines the image quality and media range of offset or liquid toner systems with the productivity and cost-efficiency of inkjet.

The technology enables printing of more than 9,000 SRA3 images per hour (or 320 A4 images per minute) on a wide range of media, including offset coated paper from 90 to 350gsm. You can produce high volumes of the full spectrum of commercial print applications, from marketing collateral and premium direct mail to catalogues, magazines and books.

With more than 90% average uptime and no need for daily calibration and maintenance, the varioPRINT iX-series enables substantial productivity gains and measurable improvements in overall running costs compared with other cutsheet production print technologies.

The new press builds on the success of the varioPRINT i-series platform introduced in 2015. With over 250 installations to date worldwide, the varioPRINT i-series has established Canon as a leader in sheetfed inkjet production printing for transactional applications, books and high-quality direct mail.

The latest iQuariusiX technology at the heart of the new iX-series combines three key innovations:

Media handling is improved with auto-detection, discard of flawed sheets before printing and precision paper transport further optimising quality and productivity. Together, these innovations deliver a balance of excellent image quality, media and application versatility, reliable productivity and cost efficiency – all in a single inkjet press. Handle short runs profitably, switch jobs quickly, and confidently produce finished documents with mixed media, while meeting demanding customer deadlines with ease.

Ayman Aly, Senior Marketing Manager B2B at Canon Middle East said: “The introduction of the varioPRINT iX-series is a significant enhancement of our product portfolio for the graphic arts market. With the varioPRINT iX-series sitting alongside Canon’s Colorado UVgel technology and ProStream continuous feed printer, commercial printers now have a broader range of Canon solutions to choose from to meet their specific business needs.”

Peter Wolff, Vice President, Production Printing Products, EMEA Commercial Printing, Canon Europe, comments: “The appeal of inkjet is its excellent productivity in the face of ever tighter deadlines and higher volumes of short-run jobs needing quick changeovers. With the varioPRINT iX-series, there’s no longer a need to compromise between quality and media range, or between productivity and cost efficiency. Commercial printers can now say “yes” to virtually any order, with confidence that print quality is flawless, media options are vast, and quick turnarounds are no problem. And all of this is achievable with the varioPRINT iX-series. Customers wanting to offer the broadest portfolio of high-quality applications now have a sheetfed inkjet press that helps them to grow their volumes, as well as manage smaller, more diverse jobs flexibly and profitably.”

Powered by a high-performance, media-driven

workflow, the PRISMAsync print

server optimises productivity by automatically setting the appropriate printing

parameters for the media selected as well as enables advance scheduling of up

to eight hours of production. Combined with PRISMA software, a completely

automated and highly intuitive solution can be integrated into any existing

workflow, covering every stage of production, from creation and print

management through to finishing and delivery tracking.